Description

Instruction

Vehicles spray booth provides a closed environment for vehicles painting with pressure controlling. As we know that dust free, appropriate temperature and wind speed are necessary for painting.

Then this spray booth can provide a relatively ideal painting environment; this can be controlled by several groups of ventilation, heating system and filtering system etc. Heated air produced by the burner can help the spray booth to hold a suitable temperature, air flow and illumination.

Our advantages

Ventilation of the spray booth

CX5 spray booth has several ventilation systems which provide better painting conditions. All the filter systems and air exhaust systems underneath create a efficiently vertical air flow; and this air flow distribute inside of the booth evenly; then this air flow make over spray removing away from the vehicle immediately and completely.

Air recirculate on baking model

100% of the air produced by the fan is transported into CX5 spray booth during the baking model; and only 15%-20% is expelled outside which means the balance 85%-80% is recovered and filled up with fresh air by means of the changeover damper.

The inner temperature of the CX5 spray booth raises rapidly; Then the heating system will power off at once when it reaches at baking temperature, this will save more energy.

Lighting

The lighting system is provided by 32pcs*36w Philip tubes with electronic ballast. They are sealed with 5mm tempered safety glass. Our spray booth lighting system is able to supply enough lighting with lower energy consume safely.

Filters

The filtering system is made up by high-efficiency filters. The filers hold higher dust retention capacity and lower resistance to the air passage. The long life designing reduces frequency of replacement, which is contributing to reductions in running costs.

Accessories

Warranty: 12 months

Lead time: 15 days

Vehicles spray booth provides a closed environment for vehicles painting with pressure controlling. As we know that dust free, appropriate temperature and wind speed are necessary for painting.

Then this spray booth can provide a relatively ideal painting environment; this can be controlled by several groups of ventilation, heating system and filtering system etc. Heated air produced by the burner can help the spray booth to hold a suitable temperature, air flow and illumination.

Our advantages

Ventilation of the spray booth

CX5 spray booth has several ventilation systems which provide better painting conditions. All the filter systems and air exhaust systems underneath create a efficiently vertical air flow; and this air flow distribute inside of the booth evenly; then this air flow make over spray removing away from the vehicle immediately and completely.

Air recirculate on baking model

100% of the air produced by the fan is transported into CX5 spray booth during the baking model; and only 15%-20% is expelled outside which means the balance 85%-80% is recovered and filled up with fresh air by means of the changeover damper.

The inner temperature of the CX5 spray booth raises rapidly; Then the heating system will power off at once when it reaches at baking temperature, this will save more energy.

Lighting

The lighting system is provided by 32pcs*36w Philip tubes with electronic ballast. They are sealed with 5mm tempered safety glass. Our spray booth lighting system is able to supply enough lighting with lower energy consume safely.

Filters

The filtering system is made up by high-efficiency filters. The filers hold higher dust retention capacity and lower resistance to the air passage. The long life designing reduces frequency of replacement, which is contributing to reductions in running costs.

| CX5-2S Spray booth Main System | ||

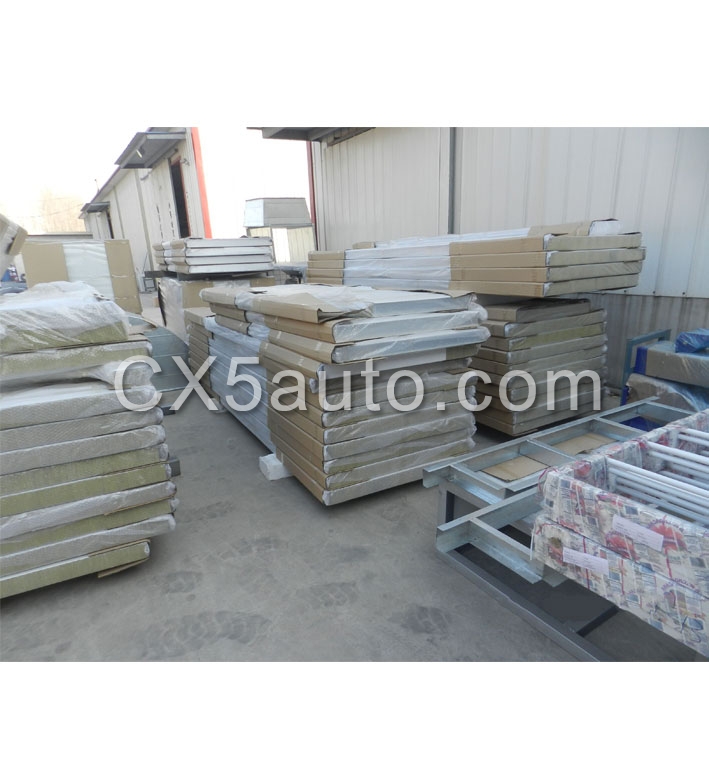

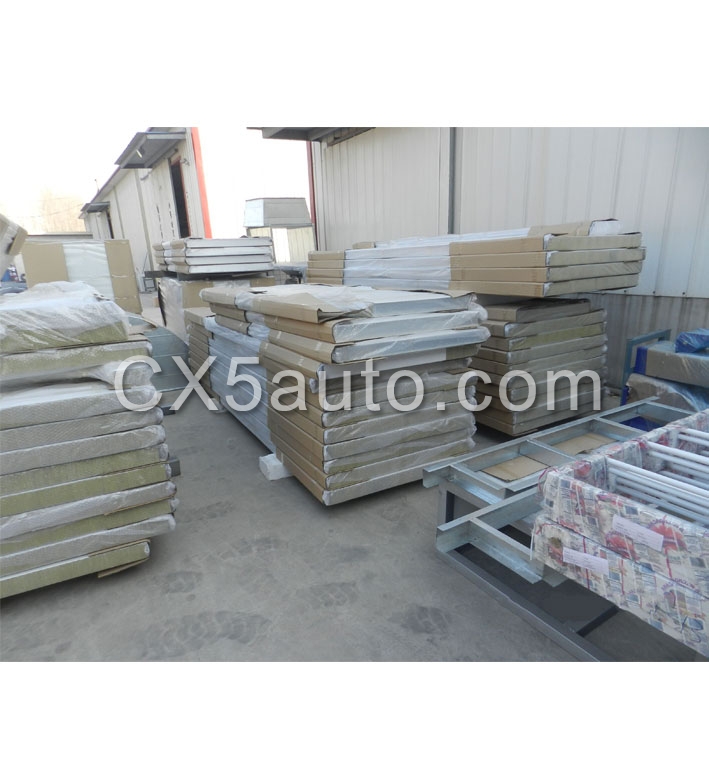

| Cabin system | Wall panel | -Sandwich style EPS 50mm thickness, width:1000mm, with0.376mm thickness steel, anti-flame and heat-insulation. -High quality galvanized steel roof panel. Optional color: white, blue, orange or red etc. |

| Basement | -Galvanized steel assemble,300mm high,quadrate steel support,2 rows of grills,3 rows of indented plates. -2 ramps,external setting,620*2000mm(W*L)/pc |

|

| Ventilation system | Inlet fan | 1*7.5KW turbo fan, air capacity: 25000m³/h, direct drive,with Siemens technology production |

| Outlet fan | 1*7.5KW turbo fan, air capacity: 25000m³/h, direct drive,with Siemens technology production | |

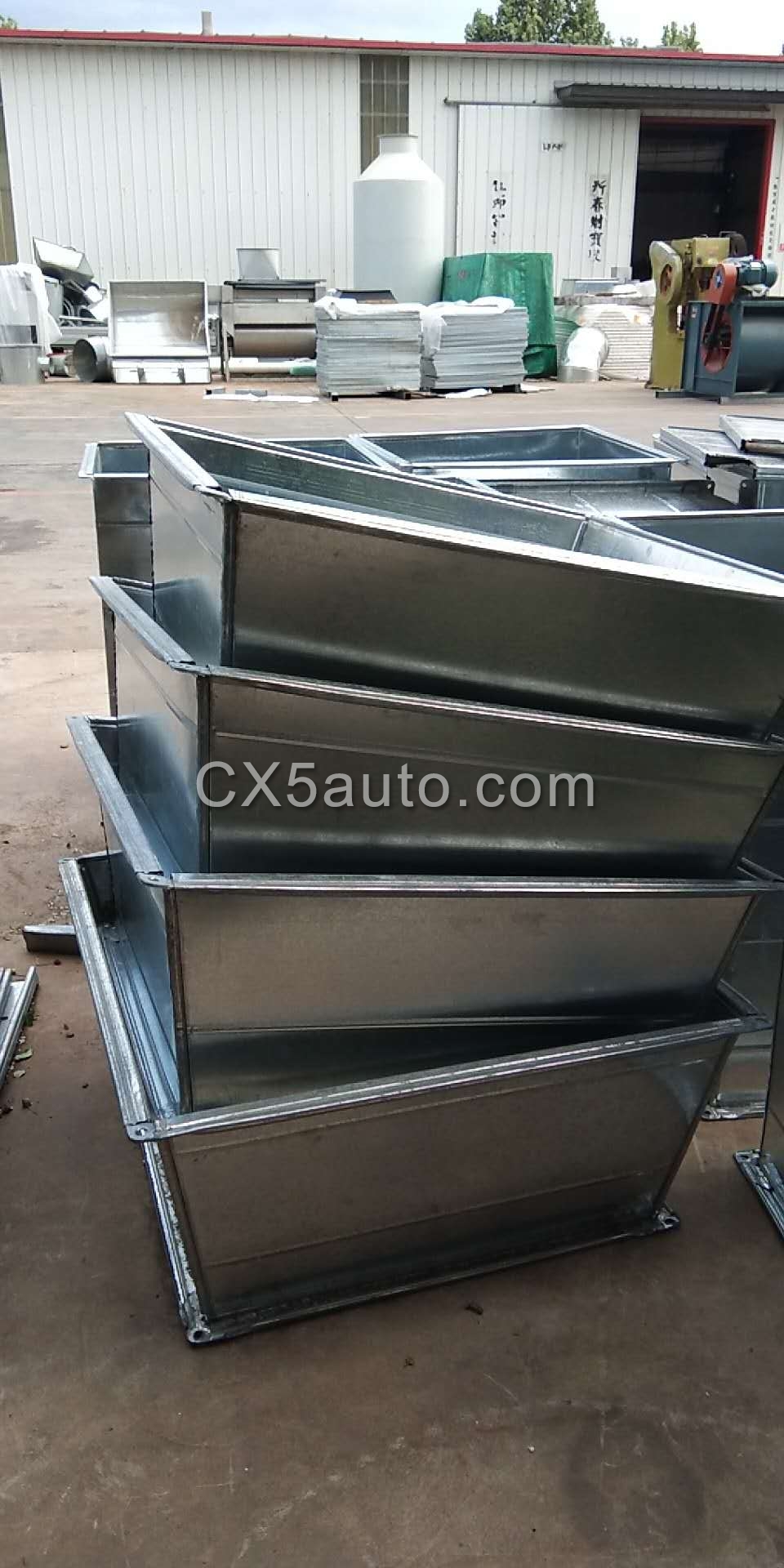

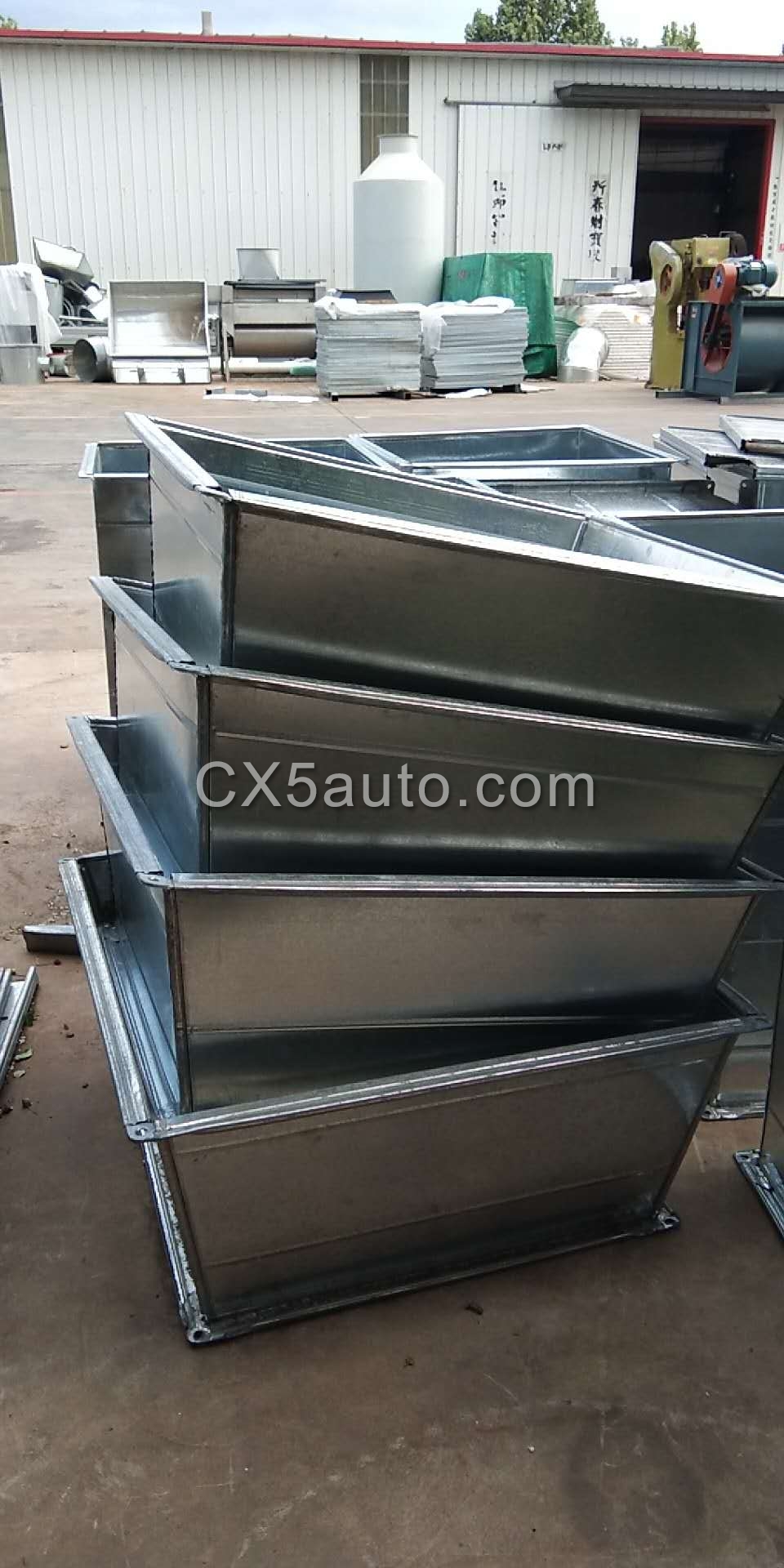

| Cabinet setting type | -Intake air from side upper ,adopt powder quadrate steel frame , strong and beautiful . -Air duct*2m long*1unit, -Elbow:90°*1 unit |

|

| Airflow speed | 0.4m/s,ventilation rate:320time/h | |

| Heating system | Burner | Italy RIELLO G20 oil burner, Max. heating capacity: 180000Kcal/h, with BELIMO 10N electric damper |

| Heat Exchanger | 1.2mm thickness SUS304 stainless steel | |

| Cabinet | Rock-wool insulation*1 unit | |

| Lighting system | Ceiling lights | 32pcs*36w Philip tubes with electronic ballast . |

| Side lights | Optional | |

| Filtering system | Primary filter | Grade G2 plate type , filtering rate>83% |

| Ceiling filter | EU5 grade high efficient filter,filtering rate>98% | |

| Floor filter | Multi-layer fiberglass filter,filtering rate>70% | |

| Control system | Control panel | Intelligent control system |

| Function | Painting, risen-temperature painting, baking, time setting, lighting, failure indication, thermostatic switch, power switch, emergency stop | |

| Voltage/Frequency | 380V,50HZ,3 phase | |

| Total power | 16.2KW | |

| CX5-2S Spray booth Parameters | |

| Outside size | 7000×5350×3400mm(L×W×H) |

| Inside size | 6900×3900×2650mm(L×W×H) |

| Entrance door | 3 folds,3000x2600 mm(W×H), bending steel without covered frame |

| Emergency door | 650*1800mm(W*H),equipped with handle lock |

| Width of entrance | 650mm |

| Height of entrance | 1800mm |

| Inlet fan capacity | 2500m³/h |

| Outlet fan capacity | 25000m³/h |

| Free air speed:(m/s) | 0.35 |

| Frequency of air exchange:(time/h) | 320time/h |

| Max. Working temperature: | 80℃ |

| Max. Heating productivity(kcal/h) | 180000Kcal/h |

| Lllumination:(Lux) | ≥1500 |

| Air filter efficiency | ≥95% |

| Noise:(db)A | <85 |

| Total power(Kw) | 16.2 |

Accessories

Warranty: 12 months

Lead time: 15 days

RELATED PRODUCTS

Paint Stands: Different types of paint stands are ...

Read more

REVIEW